James Bond Test™ MK III

|

|

|

James Bond Test™ MK III in

use on asphalt

|

James Bond Test™ MK III in

use on Concrete

|

The James Bond Tester™

MK

III or pull off adhesion test measures the bond strength

or tensile strength of concrete, asphalt, tile, concrete

repair,

or other overlay material by the direct tension or pull off method. By

pulling a 50 mm (2 inch) steel disk attached to the material under the

unit can,

- Measure the near surface strength

of a substrate in order to determine the substrates quality before

applying an overlay

- Determine the bond strength of a

repair or overlay material after it is applied to the substrate

- Determine the tensile strength of a

repair, overlay or adhesive after the material is applied to the surface

The James Bond Tester™ MK

III

has been successfully used to

verify the quality of existing materials, determine the adhesion

strength of

shotcrete, tile, epoxies, paint and other repair materials or coatings.

-

Each System comes with 10,

50mm (2 inch), ASTM Standard 1583-13 stainless steel

disks

-

Customers who purchase this may

also need the

T-M-170

Aquameter for substrate moisture testing

-

Accurate bond

strength of repair

mortars, epoxy resins, laminates, overlays, and other coatings.

-

Calibrated

gauge with maximum

load indicator and mechanical damping.

-

Ball Joint Design for rapid testing

as well as assuring direct tensile loading

-

Adjustable

alignment plate with built

in leveling facility for both

vertical and horizontal pulls.

-

Compact design.

-

Easy to use.

-

Standards

-

ISO

4624

Paints and varnishes -- Pull-off test for

adhesion

-

EN

1015-12

Methods of test for mortar for masonry.

Determination of adhesive strength of hardened rendering and plastering

mortars on substrate

-

EN

1348

Determination of Tensile Adhesion Strength

for Cementitious Adhesives

-

BS 1881 Part

207

Testing concrete. Recommendations for the

assessment of concrete strength by near-to-surface tests

-

ASTM C

1583

Standard Test Method for Tensile Strength of

Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete

Repair and Overlay Materials by Direct Tension (Pull-off Method)

-

ASTM D 4541 Standard Test Method for Pull-Off Strength

of Coatings Using Portable Adhesion Testers

-

ACI 548-30 Guide for the Application of Epoxy and

Latex Adhesives for Bonding Freshly Mixed and Hardened Concretes

-

DIN 1048

Part 2

Testing

concrete; testing of hardened concrete (specimens taken in situ)

-

ASTM D 7234 Standard Test Method for Pull-Off Adhesion Strength of Coatings on Concrete Using Portable Pull-Off Adhesion Testers

|

|

|

|

James Bond

Tester™ MK III on Horizontal Concrete Deck

|

James Bond

Tester™ MK III

on Vertical Concrete Repair

|

James Bond

Tester™ MK III

on Asphalt

|

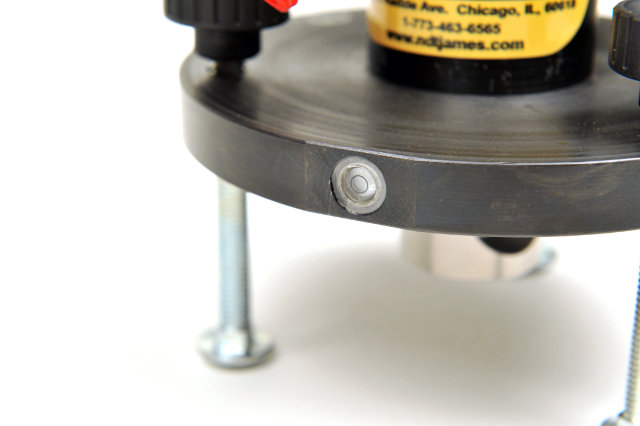

Adequate

direct tensile strength between two layers is important if repairs to

concrete structures or additional overlays on existing concrete are to

be structurally sound. The

James Bond

Tester™ MK III

involves bonding a circular steel

disk to the surface by means of an epoxy resin adhesive. A

controlled tensile force is then applied to the disk and failure will

occur at the weakest point: either in the host

material, or in the bond between overlay and

host material.

|

|

|

|

James Bond

Tester™ MK III Gauges

|

James Bond

Tester™ MK III Showing Operator View while Testing

|

James Bond Tester™ MK III gauge showing

maximum load indicator.

|

Easy to read gauges facilitate

performing the test. Two gau

ges are supplied

with each system. One for lower strength ranges, weaker

concrete, painted on overlays, etc. The other for higher

strength overlays, and concrete, mortar and asphalt repairs.

These gauges feature

- Rubberized Rugged Outer Housing

- Quick Disconnect for Rapid Setup

- Maximum Load Indicator

- Mechanical Damping to Minimize Test

Error

|

|

|

Alignment Plate

showing both horizontal and vertical levels

|

Alignment plate

showing vertical level detail

|

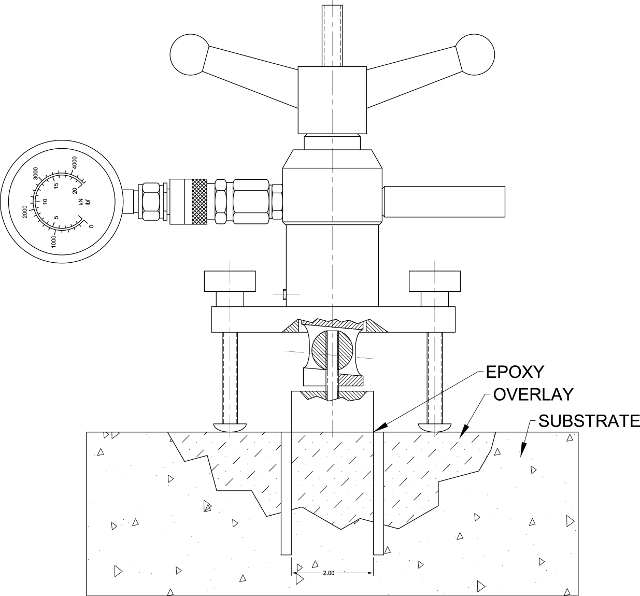

The

alignment plate has two 360 degree bubble levels built in to facilitate

set up, allowing a direct tensile pull from the surface of the

material under test. The level can be easily adjusted by

utilizing the thumb screws attached to the adjustment legs.

|

|

|

James Bond

Tester™ MK III Core Diagram

|

Core

Indicating Failure at the Bond Between the Overlay and Substrate

|

For

Proper testing, it is first necessary to cut through the overly under

test directly to the substrate underneath. In the case of

paints, thin coatings and overlays this can simply be accomplished with

a fine exacto knife or similar sharp tool. In the case of

concrete overlays, asphalts, tiles or similar repair mortars this can

only be accomplished by coring saw or drill.

Failure can typically occur in either one of three modes:

- in substrate

- at the substrate overlay interface

- in the overlay.

Tests can also be performed for verification purposes and not

to

failure. This will assure the engineer that both the overlay

and substrate have 'bonded' and further work or use can proceed.

|

|

|

James Bond

Tester™ MK III Pull Disk Being Mounted in Puller Assembly

|

Pull

Disk Mounted in Bond Puller Assembly

|

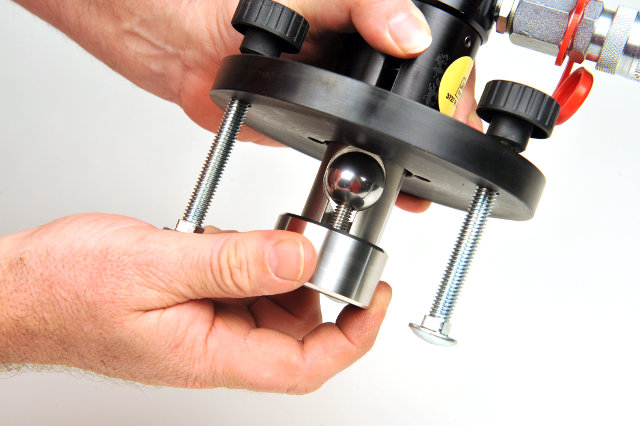

James Bond Tester™ MK III

features a ball joint pull disk design. This assures that the

pulling force is always in tension even if the pull disk is uneven due

to irregularities in the overlay surface. This also creates a

rapid test setup as the ball end of the disk simply slide into the Bond

Test Puller.

|

AlignmentPlate

|

|

Diameter

|

Horizontal and

Vertical Level

|

Easy Thumb Screw

Adjustment Knobs

|

|

150 mm / 6"

|

Yes

|

Yes

|

|

Bond Test Puller Assembly

|

|

Diameter

|

Height

|

Maximum Load

|

|

60 mm / 2.5"

|

210 mm / 8.125"

|

30 KN / 6675 lbf

|

|

Bond Test Assembly (Alignment Plate

Attached to Bond Test Puller Assembly)

|

|

Height

|

Width

|

Weight

|

|

240 mm / 9.375"

|

3010 mm / 12.5"

|

5 Kg / 11 lbs.

|

|

James Bond Tester™ MK III

in Case

|

|

Height

|

Width

|

Depth

|

Weight

|

|

410 mm / 16"

|

508 mm / 20"

|

205 mm / 8"

|

14 Kg / 31 lbs.

|

|

|

James Bond Test™ MK

III Complete System and Carry Case

|

James

Bond Test™ MK III

consists

of:

Q. Bond disk will

not stick to surface

A. The Epoxy may have been mixed with unequal parts of Resin & Hardener; causing it to not cure fully. Also, the temperature may be too cold for the epoxy to harden. Thus, more time or a higher temperature is needed for the epoxy to cure.

Q. disk pops off

surface

at a low strength

A. Surface

may not have been cleaned properly. A good indication of this would be

little bits of concrete stuck to the bottom of the disk. You may also

not have a level surface.

Q. When doing a

test to check bonding strength on a roadway, do you have to take the

test to failure?

A. Yes

and no. Make sure you follow the specs for each job you do,

some may want you to take it failure, while others may want you to just

take it to

a

certain

strength.

Q. When I crank the

handle down, the gauge does not move.

A. Chances are you need to fill the

puller with oil.

Q. How much epoxy

do I put on the bond disk?

A. You

need just a thin layer, about 3 for 4 sheets of paper.