Product Description:

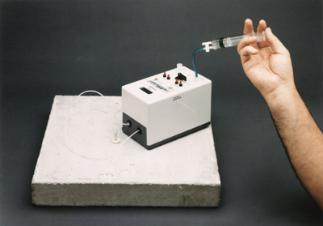

Porosiscope-Plus™

The field test

for air and water permeability of concrete using the

Figg technique.

-

Both air and water permeability are measured by the same instrument.

-

Permeability

both at the concrete surface

as well as within the concrete mass can be determined.

-

Porosity in

sealants and surface mortars can be checked.

-

The test is non-destructive (only a

small

plugged

hole required) and can be completely

carried

out on site.

-

Each test can

be completed in only a few minutes and gives reliable reproducible

results.

-

The test

enables meaningful concrete durability predictions to be made.

Tests the air

and water permeability of concrete - at the surface and beneath

Porosiscope Plus™

measures the time it takes for air to flow into a

known volume of a sealed, evacuated chamber in the concrete. While the

vacuum reduces from

-55

Kpa to -50 Kpa, a measure of air permeability is

determined. For water permeability,

porosiscope Plus™

uses the same chamber filled with water, and measures the total time in

seconds for a volume of 0.01 ml of water to escape. Surface porosity is

determined in like manner using a specially designed surface chamber.

Internal Test:

A

hole 10 mm diameter x 40 mm deep is

drilled and plugged leaving a cylindrical test void 10 mm diameter x 20

mm high situated 20 mm below the concrete surface. The time required

for air and water to permeate through the test material to the void is

used as an index to determine the quality of the con

crete under test.

Air Permeability:

The

air permeability test is always done first since moisture has a large

effect on permeability. Connect the air outlet tube on the instrument

to the

Luer connector on

the top of the hypodermic needle. Connect the hand operated vacuum pump

to the air connection on the top of the instrument and evacuate to

greater than 55

kPa. The instrument timer and

manometer will automatically show the time in seconds for the vacuum to

fall from a 55

kPa to a 50 kPa. This time is the Figg number and is a measure of the air

permeability of the concrete.

Water

Permeability

:

Connect

the water outlet tube to the

Luer socket on the top of the

hypodermic and ensure that the fine plastic inner tube is

of sufficient length to reach the bottom of the test cavity. After

filling the syringe with distilled water connect it to the water inlet

on top of the instrument. The water is then forced into the cavity and

the air displaced out through the outer tube through the overflow tube

which is 4 inches (100 mm) above the surface of the concrete. The

cavity

is filled when water starts to flow out the overflow tube. The

instrument flow sensor and timer then automatically measures the time

taken for the water meniscus to travel a distance of 50 mm and this

time

in seconds is displayed on the LCD display of the instrument. The time

in seconds is the

Figg number for water permeability.

Surface

Permeability Test

:

Measurements are carried out at the

surface by clamping a stainless steel chamber on the smooth surface of

the concrete. An exactly dimensioned cup grinding wheel is used to

smooth the sealing surface of the concrete if necessary. A measurement

of the time required

for related amounts of air and water to permeate through the concrete

is used as an index of the surface conditions. This time can then be

used to determine the condition of any concrete sealant or surface

mortar.

Surface Test

Details

:

A stainless steel surface chamber

with the same surface area and exactly twice the volume of the hole

used in the internal test is now used as the void for this test.

The method of sealing the surface

chamber to the concrete eliminates the possibility of variation in the

test due to sealants seeping into the chamber, or voids along the

sealing surface. The surface chamber is sealed to the concrete by

grinding a smooth donut in the surface with the cup wheel provided.

This

cup wheel is sized to exactly match the dimensions of the surface

chamber. A pair of o-rings mounted concentrically in the surface

testers' flange is then used to seal the chamber to the surface. The

two

o-rings eliminate the possibility of a surface void in the material

being tested defeating the test. After clamping the surface chamber to

the surface a strong seal is now provided with no variation in volume.

This surface chamber is now used as

the void for testing porosity of the surface. Rather than the walls of

the hole being the tested surface the surface that the chamber is

sealed against is now the surface tested. This provides a check for

water and air penetration through concrete sealants, surface mortars

and

any other methods used to seal construction material surfaces.

The

surface chamber has been designed to easily accommodate attachment to

the instrumentation. By first performing the air test as outlined in

the internal test and then the water test the instrumentation will

provide the time required for the chamber to lose 5

kPa vacuum or once filled with water, 0.01 ml

water.

With

the surface tester attached to the instrument both a

Figg number and direct indices for air

and water surface permeability can be established.

The

ingress of air and moisture into the concrete can cause corrosion of

the steel reinforcement and lead to a deterioration in concrete

strength. Therefore, a measure of the ease of movement of liquids and

gases through the surface layer of the concrete is a better method of

assessing the soundness and expected life of concrete than strength

alone. Permeability is recognized as being the most important parameter

in assessing concrete durability.

The

air permeability test involves measuring the time taken for air to flow

into a known volume of a sealed, evacuated chamber in the concrete,

reducing the vacuum from -55

kPa to -50 kPa. This time is a measure of the air

permeability of the concrete.

The water permeability test

utilizes the same sealed chamber in the concrete which is completely

filled with water and the total time in seconds for a volume of 0.01 ml

of water to escape is taken as a measure of the water permeability of

the concrete.

The moisture content of the

concrete has a

major effect on permeability. For example, fully saturated concrete is

almost impermeable to air and results in extremely long times in the

water permeability test.

For effective

testing the concrete should be dry and the near surface moisture

content measured. Permeability test results have show that there is a

good correlation with both water/cement ratio and compressive strength

of the concrete.

|

Weight,

complete in carrying case

|

12.0 lbs.

(5.4kg)

|

|

Dimensions

|

17 x 12 x 6 inches (43 x 30 x

15 cm

)

|

|

Power

Supply

|

Standard

9V Battery

|

|

Grinding

Wheel Rpm

|

12000 max

|

|

Measurement

accuracy

|

1 second

|

|

Operating

temperature

|

1° to 35° c

|

|

Pressure

|

-55kPa to -50kPa

|

|

Water

Volume

|

0.01 mL

|

Downloadable Instruction Manual

|