For orders outside the United States and Canada please contact us and we will be happy to get you a complete quote.

If you are not sure on what item to buy, please see our Purchasing Notes below or contact us and we'll be glad to assist you on your order.

We also offer an "Add extended warranty" option to your purchased instrument! Just add it to your cart.

Instruction manuals for this equipment can be found here:

Rebarscope® Basic Manual

Rebarscope® Complete Manual

Rebarscope® Turn On Screen

Rebarscope®- Rebar Location

Rebarscope®- component Intro

|

Product Description:

|

Rebarscope®

The digital

version of a classic

rebar locator, rebar finder

|

|

|

Rebarscope®

in use

|

Rebarscope®

Complete System

|

-

Structural

Engineers

-

Rebar

Mapping

-

Rebar

Network Analysis

-

Utility

Mapping

-

Eddy current

sensor design for

greater accuracy with built in temperature compensation, no need to

zero the sensor.

-

Single sensor

for all depth ranges.

- Separate sensor

and main instrumentation unit to scan difficult to access area's.

-

Locates

rebar, post tension cable,

conduit,and

copper pipe.

-

Rugged and

splash resistant case.

Daylight

visible display.

-

Optional Scan

Cart logs distance data as well as the location of rebar.

-

Locates up to

8" (200 mm) deep.

Determines bar

size up to 4.5" (115

mm) deep.

-

Conforms

to ACI 318, BS 1881 Part 204, DIN 1045, CP 110, EC 2, SIA< 162,

DGZfP B2.

The James Rebarscope®

is the digital version of a classic rebar locator, rebar finder which

enables the user to not only locate reinforcement bars but also

determine rebar depth and the rebar size. The

Rebarscope®

rebar locator is also capable of locating non ferrous metals as well

such as copper, aluminium, some stainless steels, wire, and more!

|

|

Rebarscope® Sensor

|

|

|

|

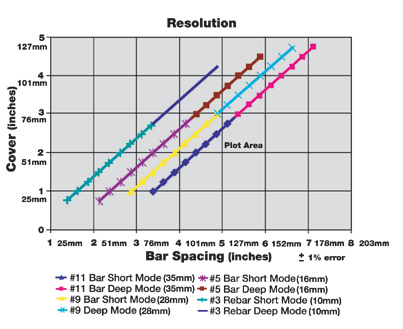

Influence

of Rebar Spacing on Results

|

|

|

|

Maximum Depth of Rebar vs Bar size

|

The eddy current

sensor is specifically designed to react to the outer surface of the

metal object.

It is uninfluenced by small metal particles in the concrete, whether

the concrete is fresh or hardened, wet, or dry. The eddy current sensor

also allows the unit to locate both ferrous as well as non-ferrous

metals in concrete and other non-metallic construction materials.

This sensor has also been designed with temperature

compensation circuitry as well. The temperature compensation

circuitry not only improves accuracy and performance but allows the

operator to use the equipment without a "zero" procedure first.

As always only one sensor is required for all depth ranges

and functions of the equipment.

The

latest in microprocessor technology not only conditions the signal from

the sensor for more accurate and dependable results but provides the

user with the information they need. Rebar diameter can be estimated by

using a simple system of comparison. All this is fully automated for

consistent,

repeatable results with increased resolution over previous models.

The

microprocessor can also statistically analyze the data, searching

automatically for minimum cover points, and the least cover of a group

of points. A Cover Map

or display of cover

points as a symbolic map of a

structure can assist the user in finding

problematic areas. Built in

memory can store over 80 thousand individual data points

for later processing.

|

|

|

Rebarscope®

with Head Phones

|

Rebarscope®

in Hard to Reach Location

|

Feedback

to the user can also be made via the direct view, sunlight readable

digital screen, or via head phones. By seperating the sensor

from the main instrumentation unit, difficult to reach area's can be

handled with ease.

|

|

|

|

Rebarscope®

used on Wall with Scan Cart

|

Rebarscope®

with Scan Cart

|

Rebarscope®

with P.C.

|

The

optional Scan Cart

can be used to graphically display

a cross section

of the concrete and the location of the metal objects within. With its

built in encoder objects can be

located with both

distance and depth recorded.

Rebarlinx® the

fully

integrated P.C. software allows the

upload and storage of data points via USB. The

ruggedized Rebarscope® provides the field

engineer/technician with

all the tools necessary to locate and determine what and where all

metal objects are within the structure.

|

Main

Unit

|

|

|

Weight:

|

5.4 lbs

2.5 Kg

|

|

Size:

|

10.63" L x 9.68" W x 4.88" H (27 cm x 24.5 cm x 12.4 cm)

|

|

LCD Size:

|

320 x 240

pixels

|

|

LCD Dim.:

|

3.5" L x 4.65" H (8.9 cm x 11.8 cm)

|

|

Recharging

Voltage:

|

18 V

|

|

Memory

Capacity:

|

80

thousand data points

|

|

Battery

Life:

|

4 - 6 hrs

continues run time

|

|

|

|

|

Probe

Dimensions

|

|

|

Weight:

|

1 lb 0.45 Kg

|

|

Size:

|

5" L x 2.4" W x 1.6" H (12.7 cm x 6 cm x 4.1 cm)

|

|

|

|

Scan

Cart Dimensions

|

|

Weight:

|

1 lb 0.45 Kg

|

|

Size:

|

8.25" L x 5.6" W x 2.25" H (20.1 cm x 14.2 cm x 5.7 cm)

|

|

Maximum

Scan Length:

|

48 ft.

14.6 m

|

-

R-C-400

BASIC UNIT

includes the following: Main Unit, Probe, 8 ft Cable, Sizing Template,

Charger, and Headphones

-

R-C-450 BASIC

UNIT WITH SOFTWARE

includes the following: Main

Unit, Probe, 8 ft Cable, Sizing Template, Charger, Headphones, USB

Cable, and Basic Software.

-

R-C-475 SCAN

CART UPGRADE

includes the following: Scan Cart, 2 Extension Rods, 12 ft Cable,

Scanning Software.

Turns

your Basic Unit into a complete system (R-C-410).

-

R-C-410

COMPLETE SYSTEM

includes the

following: Main Unit, Probe, 8 ft & 12 ft Cable, Scan Cart,

Headphones, Charger, Complete Software (Basic and Scanning Software),

USB Cable, Sizing Template,

2 Extension Rods

Rebarscope_Complete_Data.pdf

Downloadable Instruction Manual

|

|