Product Description:

IQM-Meter™

The

James IQM System enables fresh concrete to be easily and completely

monitored in the field for improved

safety, quality assurance and optimum setting time.

-

Premature

Form Stripping in cold weather

can be avoided.

-

Excessive

summer heat exposure is controlled.

-

Loading,

prestressing

or post tensioning as well as lifting and/or form removal can be

performed safely

-

Optimum

scheduling of form removal, prestressing, post tensioning, and highway

loading.

-

Artificial

heating and cooling of concrete is minimized

-

Rework due to

concrete not fully cured is reduced.

-

Modular

design facilitates optimum number

of monitoring locations.

-

A

visual indicator shows field personnel that the required maturity is

reached at each location.

-

Construction

personnel with minimal training can easily implement monitoring

function.

-

Multiple use

thermocouple sensor lowers costs.

-

Documented

quality control of each pour.

-

Faster

and safer form stripping.

-

ASTM

C-1074 & ASTM C-918

Designed

specifically for monitoring and analyzing fresh concrete, the IQM™ Module is

programmed with the required

Equivalent Age of the concrete under test. Once this preset maturity

number is reached, a visual indicator will flash continuously,

providing

an effective, automatic indication that the concrete has reached the

desired level of maturity.

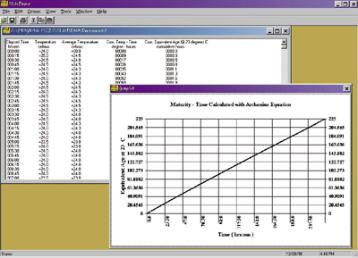

Software and

interface cable allow direct

uploading of the data to a Windows PC environment where it can be

imported into any spreadsheet, word processor or graphing program for

further analysis. Temperature history can be graphically displayed with

respect to time.

The IQM™ software will

create maturity indices from the complex

Arrhenius equation according to ASTM procedure. The strength gain can

be calculated and all these parameters can be graphically displayed

with

respect to time. The

James IQM System™ enables fresh

concrete to be easily and completely monitored in the field for

improved safety, quality and optimum stripping time. Its modular design

facilitates number and choice of monitoring locations.

The system

generally consists of multiple units of M-IQM-4011 units on the

structure logging the temperature and programmed with the proper

activation energies. These monitor the critical and most temperature

sensitive area's of the structure. Each unit is connected to a single

thermocouple (M-IQT-4011). The units are then programmed with the M-IQM-4040 software

and a P.C.. Once the concrete has reached the proper cure point the

temperature time history can be retrieved with

the software (M-IQM-4040).

This makes the IQM System™ flexible to

accomodate a single location or multiple locations on a structure.

Typical

Application

A multi level concrete building is

under design and its construction is to be controlled with the IQM-Meter™

to meet performance specifications.

Laboratory

tests indicate that the concrete specified is of satisfactory quality.

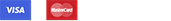

The maturity vs. strength

relationship obtained during laboratory tests is shown in the figure

below.

The structural

engineer has specified that the slab forms can be removed when the

concrete has reached a minimum strength 3500 PSI. To allow for

unanticipated variations in the concrete properties, the contractor has

decided that he will remove the forms when the concrete strength is at

least 5% greater than the required 3500 PSI, i.e., when strength is

3675

PSI. The figure below shows that this strength level will be reached

when the maturity is 59 Hrs.

The IQM-Meter™ thermocouples, therefore

should be inserted in the freshly placed concrete at critical

locations.

The modules should be programmed with an equivalent age of 59 hours.

Once the light on the last meter starts flashing, maturity value has

reached 59 hours and the forms can be removed.

The

IQM System

The

temperature history is recorded by the IQM-4010 K

Thermocouple Module, which can store over eight thousand temperature

readings. Intervals between readings are specified by the user and can

vary from one minute to twenty-four hours. Designed with the latest in

microcomputer technology, the module is rugged enough for the harshest

construction environments.

The

module is programmed with the required Equivalent Age of the concrete

under test. The red light on the module will flash continuously once

this number has been reached. This provides a simple and effective

automatic indication that the concrete has reached the desired level of

maturity at that location.

Generally,

sensors are inserted at critical points subject to the most extreme

temperatures. Using the modular IQM-Meter™ System, there

is no limit to the number of sensors that can be embedded in the wet

concrete. The sensor giving the lowest maturity number indicates the

area with the lowest strength, and this sensor will be the last to

signal that the desired maturity has been reached.

The economical

M-IQM-4040

PC Software and

cable interface allow direct uploading of the data to a Windows

environment P.C. The data, then, can be easily imported into any

spreadsheet, word processor, or graphing software package for further

analysis. Temperature history can also be graphically displayed with

respect to time. The IQM™ software will

create maturity indices from the more complex Arrhenius equation

according to ASTM procedure. Strength gain can also be calculated via

accepted methods. All of these parameters can be graphically displayed

with respect to time.

Theory

The maturity

method is a technique for predicting strength based on the temperature

history of the concrete. The extent of the cement hydration depends on

how long the concrete has cured and at what temperature. Maturity is a

measure of how far the hydration has progressed.

The equation

developed by Arrhenius allows for greater variation in cement types. It

assumes a non-linear relationship for the determination of a maturity

index and is suitable for a wide range of temperatures. The mathematics

of the Arrhenius equation is more complex but it gives more accurate

strength predictions

over a variety of cement types. The maturity index is expressed as

equivalent age in hours referred to a specific temperature, and is a

function of time, temperature and the activation energy of the cement.

|

MODEL

M-IQM-4010:

|

K-Thermocouple

Module

|

|

MEMORY

SIZE:

|

>8000

Data Points

|

|

MEMORY

TYPE:

|

Non-Volatile

|

|

BATTERY

TYPE:

|

1-9 V

Battery

|

|

BATTERY

LIFE:

|

@20°C:

30 Days recording every 30 Minutes

|

|

INTERVAL

BETWEEN READINGS:

|

From

1 Min. to 24 hrs. in Minute Increments

|

|

RECORDING

TEMPERATURE RANGE:

|

-20°C to 100°C

|

|

OPERATING

TEMPERATURE RANGE:

|

0°-70°C

|

|

DIMENSIONS:

|

1.5 x 2.5 x 5

inches (38mm

x 63 x 127mm)

|

|

WEIGHT:

|

10

oz (280 grams)

|

|

MODEL

M-IQM-4011:

|

3 Ft (1 m) K-Thermocouple

(included

with every M-IQM-4010 System

accuracy ±1°C)

|

|

MODEL

M-IQM-4040:

|

Software

to calculate

maturity & strength

|

|

OPERATING

SYSTEM:

|

Windows

9x / ME

|

|

PROCESSOR:

|

166 MHz

Pentium or faster

|

|

RAM:

|

32

MB

|

|

HARD

DISK SPACE:

|

8 MB

|

|